Solar and wind farms are gaining traction in Texas and across the country. As eco-friendly and durable ways to provide energy, these farms are popular choices to utilize instead of fossil fuels.

Any construction project—especially those as big as solar and wind farms—requires heavy hauling and trucking from aggregate hauling companies like Twisted Nail. With so many solar and wind farm jobs popping up around the state, we’re committed to providing top-notch heavy hauling services.

The Popularity of Solar and Wind Farms in Texas

Texas is among the leading states in terms of solar and wind farms, and more projects are underway. In central Texas especially, there are more than a dozen of these mega projects in the middle of production or planned for this year. These developments include a 270-MW solar project for a Texas petroleum producer by Black & Veatch, several projects by Primoris Services Corporation, wind projects in the Taylor and Nolan Counties by Blattner Energy, and a western Texas solar project also by Blattner.

While the solar and wind power industry was just starting out a decade ago in Texas, the state now generates more than ¼ of all wind power in the country with over 25,000 jobs. Solar has also been a rapidly growing industry, with reports that Texas has 532 solar companies and boasts nearly 35% of the national total of solar jobs. The state has certainly proven to be a leader in the fields of solar and wind energy.

Aggregate Materials Needed to Complete These Jobs

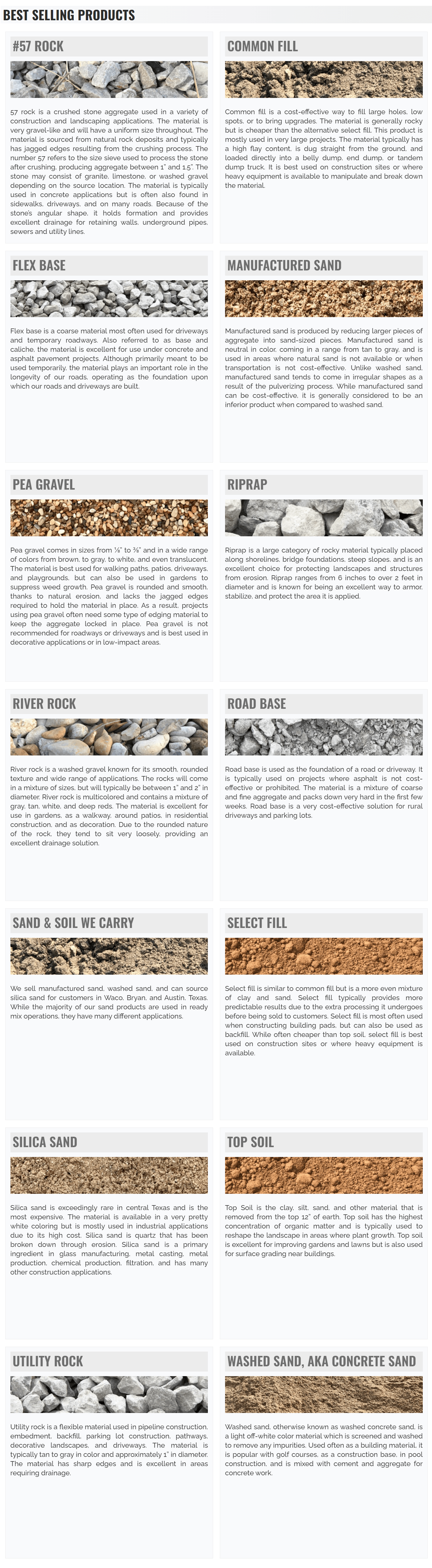

Solar and wind farms are massive projects, requiring up to a full year of commitment from everyone involved, and each phase requires a different kind of aggregate material. In general, the most common materials used throughout the project include Road Base, Select Fill, Washed Rock, Pea Gravel, Washed Sand, and Rip Rap.

1. Road Base is particularly helpful at the start of a project, as it is a relatively simple foundation for office pads and access roads. Many companies also rely on Road Base throughout other stages of projects to build various pads, staging yards, and roads.

2. Select Fill, like Road Base, is commonly chosen for various foundational pads. While it’s not a staple material, it’s a good type to have around to use as needed.

3. Crushed Washed Rock is used in readymix plants. About 3/4” to 1” of Washed Rock is needed, and the plants are brought straight to the jobsite because solar and wind farms require so much concrete. It’s more efficient to bring the plant to the jobsite rather than delivering the concrete in huge amounts. Plants rely on aggregate hauling companies to stockpile the rock that goes into the readymix concrete. Another use for Washed Rock is to prevent too much electricity from traveling through the material, so the electrical teams rely on this type of rock as well.

4. Pea Gravel serves the same purpose as crushed Washed Rock, except it is not used for electrical purposes. Because pea gravel is made of crushed stone and has similar qualities as Washed Rock, it is also used in readymix plants, though only about 3/8” of Pea Gravel is used compared to the larger amount of Washed Rock.

5. Washed Sand is used for similar purposes as Washed Rock and Pea Gravel, with the main difference being its quality of looseness since it is a type of sand instead of rock or gravel. Like Washed Rock, it can be used by electrical technicians to limit the amount of electricity traveling through the material.

6. Rip Rap serves an entirely different purpose from the other types of rock and sand and is most often used to help maintain pad or entrance structure. It can also be used to fill large areas.

Quantity of Trucking Needed

With solar and wind farm construction lasting anywhere from 30 days to a year, the quantity of trucking varies from project to project. If it’s a larger project, such as for industrial purposes over a huge amount of land, there will evidently be more trucks required to haul more materials. However, the trucking for these projects comes in waves, with some companies needing 30 or more trucks over a couple months and then never needing trucks again. Others are more spread out, with a steady supply of materials and trucks coming through during the entire process. At the same time, companies which choose to set up a readymix plant may need less trucks because they have a plant to make concrete right on the jobsite, but still occasionally need haulers to deliver the rock that goes into the plant. Again, much of this quantity depends upon the size and duration of the project.

Heavy Hauling Requirements for Solar and Wind Farms

Aggregate and hauling companies must be prepared for whatever comes their way during a solar or wind farm project. Due to the unpredictability of what these projects will need for how long, it’s a good policy to expect the unexpected.

Depending on the quantity and type of material needed, there are different heavy hauling guidelines. For example, if a project is hauling mostly Washed Sand versus rock or stone, there are different vehicles required to transport sand rather than rock. In addition, there are other materials besides rock and sand which are required for solar and wind farms and are specific to these projects. That being said, there are special hauling requirements for these materials, which can include blades, nacelles, hubs, tower sections for wind turbines and solar panels, and foundations for solar farms.

Many of these materials would fall under oversize/overweight guidelines, which are listed on the Texas Department of Transportation’s website. As a result, a special permit would be required to transport these items. Other special requirements could include bringing pump trucks, cranes, and fire trucks to the job site, depending on the project. Some materials need specific equipment in order to be transported, including steerable trailers and dollies. As with many oversize loads in Texas, escorts may also be required.

Contact Twisted Nail for Solar and Wind Farm Trucking

With so many solar and wind farm projects popping up around Texas, you can rely on our experts at Twisted Nail to provide you with stellar trucking and heavy hauling services. From laying the foundation to the final stages, we’re with you all the way and are ready to support each project. Contact us today to start your aggregate hauling journey with us!