What Is a Dump Truck?

The label ‘Dump Truck’ encompasses a wide range of equipment that can be defined as a semi-truck with a dump bed attached to the truck frame. Dump trucks are known by several different names: dump truck, tandem, tri-axle, quad-axle, and super dump. The names stand for the number of axles that the truck has; the number of axles helps to determine the carrying capacity of a specific unit. Dump trucks are utilized on jobsites that have limited space or that are located on roads that cannot accommodate a full truck and trailer combination. Dump trucks can be used in a wide variety of ways including material and aggregate hauling as well as demolition.

The Mechanism Behind Dump Trucks

Dump trucks are the most basic kind of truck used to haul materials such as stone, sand, and gravel. Like many other types of trucks, dump trucks come with a hydraulic lift that automatically raises the dump box to unload materials. The most popular types of lifts include telescopic, dual-piston, and scissor lifts.

1. Telescopic lifts involve a single cylinder which lifts the dump bed as far as it can go, nearly at a 90 degree angle. These types of lifts are usually located in the center of the dump box’s front end.

2. Dual-piston lifts simply use two pistons—instead of a single one—to lift the dump box.

3. Scissor lifts are the most popular kind of lift for dump trucks. This system is easy to use and helpful with uneven loads. Using one cylinder that functions like a pair of scissors allows for maximum leverage while also allowing enough space and power to balance uneven loads.

All hydraulic lifts come with a battery that needs to be replaced every so often. However, some lifts don’t use battery when using the “gravity down” option, and others can save battery by only using it when lowering the dump box.

What to Look for When Buying a Dump Truck

For owner-operators and construction businesses that frequently haul aggregate in bulk, buying a dump truck could open their operations to contracts that traditional equipment will be unable to service. Here are some factors you should be aware of when buying a dump truck.

1. Size and weight

Before using a dump truck, it’s important to verify that all your materials will fit in the dump box and meet the weight requirements (most dump trucks of average size can carry up to 10-25 tons).

When purchasing, considering the businesses average use is important; while there are Super Dump dump trucks that can carry 25 tons of material, the trucks can be prohibitively expensive and may be overkill for a landscaping company. By contrast, if a business is frequently stockpiling, then the extra investment required for a higher capacity truck will make each mile driven significantly more profitable.

2. Dump box durability

Many dump trucks these days come with aluminum boxes. Aluminum is more lightweight and rust-resistant than steel, which helps them last longer, but they are not as durable as steel dump boxes and cannot handle as many rough materials. An aluminum dump bed is excellent for stockpiling but cannot be used on demolition projects or to haul material larger than your fist. A steel dump bed is heavier, and therefore has a lower carrying capacity, but is able to be used on a much wider range of jobs.

3. Side wall tubing

Most often, your average dump truck comes with 2×2 or 2×3 side wall tubing. While there is nothing wrong with either of these types, 2×3 is recommended for heavier loads because it is more durable.

4. Width of the truck

Trucks that have a wider dump box canhold more materials, but this may not mean they can carry heavier loads. The larger the dump box, the heavier it is, which will count against the truck’s legal payload limit. Conversely, a dump truck with a smaller dump box may be lighter but may not have the capacity to carry up to the trucks legal maximum weight. Wider boxes are perfect for bulk loads that need to travel over long distances.

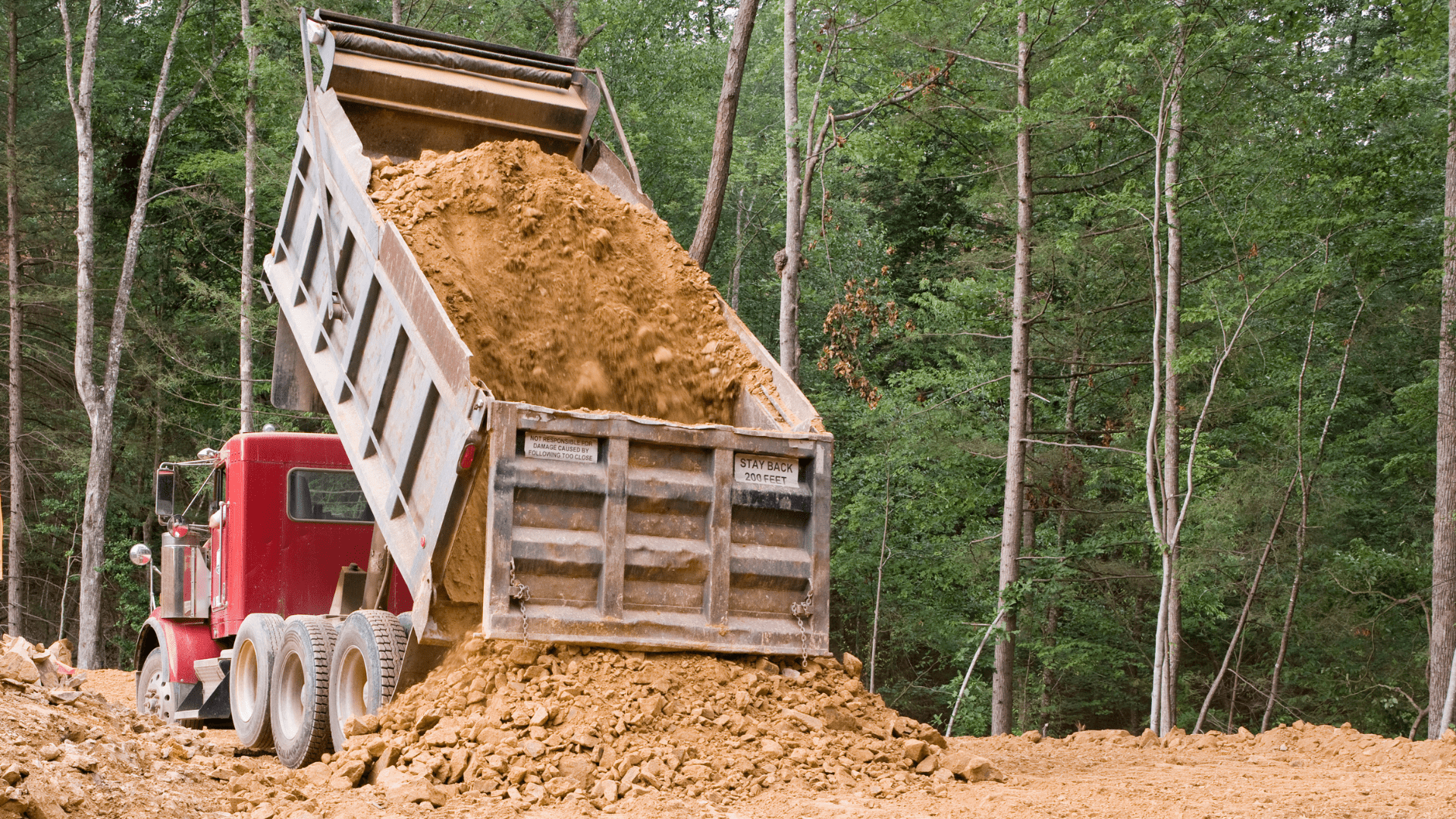

What You Can Haul with a Dump Truck

Dump trucks can transport any kind of loose material, such as gravel, rocks, sand, or demolition waste. Their open-box beds powered by hydraulic lifts make the loading, hauling, and unloading process quick and seamless.

Dump trucks are equipped to handle most loads And are more versatile than tractor-trailer combinations. Weight limits for dump trucks range from 10 to 25 tons; anything heavier is better suited for a tractor-trailer. There are many different types of dump trucks which provide a wide range of options for aggregate haulers.

Small-sized standard dump trucks are good for hauling lighter loadswith a maximum load weight of 10-15 tons. On the other hand, larger or full-sized dump trucks can handle up to 25 tons. Transfer dump trucks, which use a standard-size transportable cargo box, can generally haul up to 15-18 tons.

While dump trucks are perfect for industrial and residential construction projects, as well as general aggregate hauling, they are not good for heavier projects. Compared to trailers which can handle heavier loads, dump trucks have a shorter wheelbase, which limits how much and how heavy they can carry. A good alternative in these cases is an aluminum or steel end dump trailer.

However, if your project doesn’t require any major lifting or specifications, a dump truck is a cost-effective choice.

Learn How Twisted Nail Can Help Find You a Dump Truck in Texas

Whether for commercial or residential use, dump trucks are an essential part of any construction or hauling project. They make moving tons of material quick, easy, and cost-effective. With a variety of types and sizes available to buy, you can rest assured that there’s a dump truck suited to your needs.