Recycled concrete is a durable construction material made from concrete which has become too worn down to stay in use, so it’s a sustainable and easy-to-use option for construction projects. Recycled or crushed concrete, does not take the place of poured concrete, instead this product can be used as a substitute for more expensive construction aggregates. By taking old concrete and crushing into reusable pieces, you can save money, time, and effort on your next job site.

If you’re looking to learn more about the uses and benefits of recycled concrete for your next commercial project, or if you’re looking for recycled concrete hauling services, you’ve come to the right place.

Why Recycled Concrete Makes Financial Sense for Construction Jobs

Using new concrete for every construction project can get pricey, but if you switch to using recycled concrete, it will save you large expenses that you would have otherwise incurred. Plus, it will save you from going through the process of looking up proper concrete disposal laws and finding a disposal facility in your area.

Any recycled aggregate is a better financial choice because it saves you money and effort that would have been needed for securing, processing, and transporting any new construction material. And, if you’re extremely financially conscious, you’ll want to use the recycled concrete to build or repair within the same location as where it was demolished. This saves more money, especially regarding transportation, because all the materials can remain in the place where they were originally used.

Not only does using recycled concrete make sense for financial reasons, it is a more sustainable choice and is a great way to be more environmentally conscious with each construction job. If every major construction project used recycled materials, imagine how much the positive environmental impact could be increased and the carbon footprint reduced. Because of both the environmental and financial benefits, recycled concrete is a superior choice for your next job site.

Types of Job Sites That Need Recycled Concrete

To give you a better idea of how you can take advantage of recycled concrete, here is a list of 5 popular job sites that can use recycled concrete. You may be surprised to learn how versatile it can be!

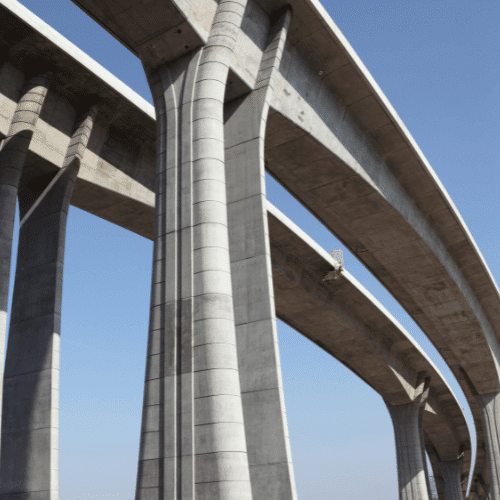

1. Highways

Using recycled concrete can help save a lot of time, money, and effort in the creation and expansion of highways (or any roadways that have a pre-existing layer of concrete). Since a concrete layer is already present, there is plenty of concrete available to recycle and use to repair, build, or expand existing highways.

2. Parking Lots

Like with roads, parking lots can be made from recycled concrete—especially since it can be used to make aggregates which are strong enough to handle large numbers of heavy cars and other vehicles. Just because it’s recycled doesn’t mean it’s any less durable than new concrete!

3. Driveways

This one may seem obvious after listing highways and parking lots, but since driveways are one of the most common job sites which use concrete, we think it’s important to mention it here as well. Similar to roads and parking lots, recycled concrete can be used for residential projects like driveways.

4. Landscaping

Recycled concrete isn’t just for roads, though—it’s an extremely versatile material that can also be used for landscaping and decoration. More specifically, it can be used to build retaining walls, raised flower or garden beds, or yard drainage systems.

5. Sidewalks

Sidewalks and other community paths can also benefit from using recycled concrete—which can even be turned into decorative concrete if you’re looking to add some flair to a hiking path, sidewalk, or patio.

Trailers We Haul Recycled Concrete With

Our best recommendation for hauling recycled concrete is using a steel end dump trailer, which is a great option for large or overweight hauls. The way end dumps work is by delivering the material through a back gate that is raised from the front and then dumps out the material.

Something important to remember when hauling recycled concrete with an end dump trailer is that the trailer must be placed on level ground. Otherwise, the trailer may not remain stable and could result in a poor job.

Other popular hauling options include aluminum end dump trailers and dump tracks, but we prefer to use steel end dump trailers over aluminum end dump trailers or dump trucks because they are a more durable choice and can handle rougher and heavier materials.

Contact Us for Recycled Concrete Today

For all your hauling material needs, we’re your go-to provider. We offer recycled concrete services in the Waco, Bryan, and Austin areas of Texas, so if you’re looking to make an environmentally- and pocket-friendly move for your next construction project, contact us for recycled concrete today.