Sand is one of the most important components of any construction project, providing a solid base and adaptability that can’t be beat. If you’re looking for a certain type of sand for your job site, or if you are wondering which type of sand is best for your project, look no further—we’ll cover everything you need to know about the most common types of sand and what they’re used for.

A Brief History of Sand on Job Sites

Sand is one of the most essential materials involved in construction and is an extremely versatile material. Using sand for construction projects has many benefits, including being strong, flexible, and adaptable.

While sand can be used on its own—such as for playgrounds or sand pits—it is most often used with other materials to make it the strongest and most durable it can be. In addition, sand can be used in the walling and flooring of specific buildings or for decorative purposes.

In Texas, there are four main types of sand you can source from our quarry connections—let’s delve deeper into each type and what they are most commonly used for.

Common Types of Sand Used in Construction

Manufactured Sand

Manufactured sand is, as you may have guessed, formed artificially by crushing large pieces of aggregate into tiny pieces until it eventually becomes sand. While manufactured sand is not as popular as washed/concrete sand, it does have benefits, such as being cost-effective and widely available in areas where natural sand is too difficult to find or too expensive to transport. Most manufactured sand comes in neutral colors, such as tan or gray, and comes in irregular pieces due to the crushing process.

Silica Sand

While silica sand is rare in Texas, we can source it for you and make sure you get the specific type of sand necessary for your job site. Silica sand comes in an aesthetically pleasing white color, as it is quartz broken down by erosion. This type of sand is the primary ingredient in glass manufacturing, metal casting, metal production, chemical production, and filtration, though it has many other construction uses as well.

Due to the difficulty involved in sourcing silica sand, it can get quite expensive, which means it is often used for bigger projects like industrial construction jobs. But it’s worth the price if it will make your job site the most successful it can be!

Washed/Concrete Sand

Washed or concrete sand is produced in quarries and comes in an off-white color. It gets its name from the process of screening and washing, which removes any impurities. While it’s often used in building foundations when mixed with other materials (such as with water and cement to form concrete), it does not provide a good base on its own.

This type of sand is often used for walkways, patios, golf courses, and pool construction.

Fills

There are two main types of fills: select fill and common fill. Each is made up of tiny pieces of rock, which can be made naturally or artificially. Additionally, because fills are compact, they are helpful for building in areas which are prone to getting wet or which have many holes to fill.

Select fill and common fill have many similarities, but the main difference is that select fill is a more even mixture of sand and clay because it goes through a different type of processing. In addition, common fill is cheaper than select fill and is generally used in large construction projects. Because common fill is a rockier type of sand, it is often used in projects where heavy equipment is available to break it down.

Types of Job Sites That Need Sand

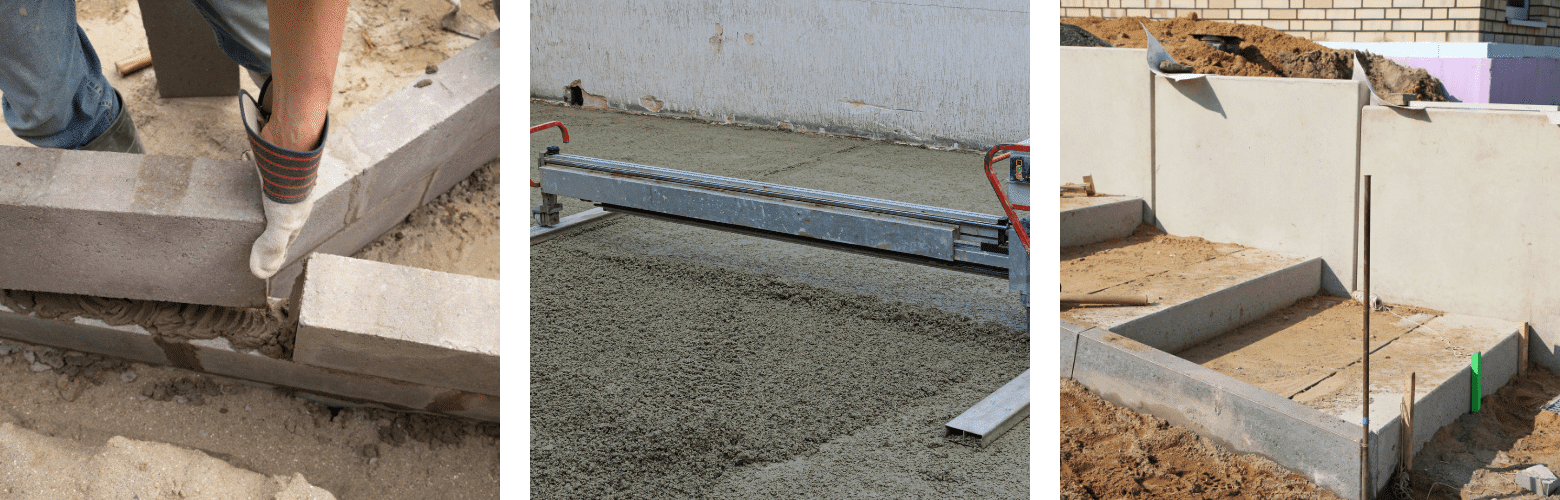

Walls & Flooring

Clearly, sand is important in nearly every type of construction project. However, there are some specific job sites that require sand that may surprise you—such as walls and flooring.

When constructing a building, one of the most important aspects is the walls and flooring that will hold it up. Sand can be easily compressed and therefore is an essential component of walls and flooring, but it becomes stronger and more durable when mixed with other materials like water or cement.

Landscaping & Decoration

Sand is also used for more aesthetic purposes, such as in landscaping or outdoor decoration. While concrete, rock, or gravel will serve their purpose for job sites such as walkways, patios, and the perimeter of pools, using a mix of sand and other materials gives each site a more aesthetically pleasing look while remaining strong and durable.

Playgrounds

Even places like playgrounds need careful consideration of materials before construction begins. Sand is a great option for job sites that see high foot traffic because it will not wear away and, for playgrounds in particular, provides a softer surface than gravel or concrete.

Trailers We Haul Sand With

Steel End Dump Trailers

If you’re looking to transport a large or overweight load, a steel end dump trailer might be the best option for you. End dumps allow you to deliver your payload through a back gate that rises up and dumps out the material. Because of the position end dumps must attain, they need to be placed on level ground in order to remain stable.

In general, end dumps are useful for hauling construction materials, aggregate stockpiles, and agricultural materials. In particular, steel end dump trailers are perfect for demolition hauls or large loads of rock or gravel, and they are more durable than aluminum end dump trailers and can therefore be used daily.

Aluminum End Dump Trailers

Aluminum end dump trailers are a lighter alternative to steel trailers. While they can’t handle as much rough or large material as steel trailers, they are flexible and durable like their steel counterparts. Loose aggregates like sand are perfect for aluminum end dump trailers because the lightweight design allows them to pull the maximum payload of looser materials. Due to their light weight, they can be pulled by a small tow vehicle and are excellent over long distances.

Dump Trucks

Not every project requires a specific kind of end dump trailer, especially if you’re not doing any major hauling. In these cases, a dump truck (also known as a tandem) would be your best option.

Dump trucks can transport any kind of loose material, such as gravel, rocks, sand, or demolition waste. To aid you with all your sand hauling and transport needs, dump trucks are equipped with an open-box bed that can be lifted at the front in order to dump out the material.

While dump trucks are perfect for construction projects, residential deliveries, and aggregate hauling, they are not good for heavier projects (over 15-17 tons). Due to their flexibility and shorter wheelbase when compared to trailers, dump trucks cannot handle as much of a haul. In these cases, a steel or aluminum end dump trailer is the better option.

Contact Us for Construction Sand Today

Through our wide range of quarry connections, we can ensure that you receive the right sand for your project in a time- and cost-efficient manner. Our team specializes in aggregate hauling and material hauling services, so we’re here to help you with all your construction sand needs.

Not sure what type or how much sand you need? Looking for a professional opinion? If you’re in the Austin, Bryan, or Waco areas of Texas, give us a call today, and we’ll be happy to help!